Affordable and Long-Lasting Tint Pros Vinyl Wraps for Private and Corporate Use

Affordable and Long-Lasting Tint Pros Vinyl Wraps for Private and Corporate Use

Blog Article

The Ultimate Guide to Selecting the Right Plastic Covers for Your Task

Choosing the suitable plastic wrap for your project requires a nuanced understanding of various variables that affect both aesthetics and functionality. From differentiating in between cast and calendared plastic to examining the effects of various finishes, each choice lugs weight in the overall outcome. Furthermore, the relevance of installment methods can not be ignored, as appropriate application is important for accomplishing durability and aesthetic appeal - Tint Pros Vinyl Wraps. As you browse these considerations, it comes to be clear that the path to an effective plastic cover project is layered with vital decisions that warrant additional exploration.

Types of Plastic Wraps

When selecting plastic wraps, understanding the various kinds readily available is essential. Plastic covers can be extensively categorized into two main types: cast vinyl and calendared plastic. Cast plastic is recognized for its superior top quality, adaptability, and longevity, making it perfect for complicated surface areas and long-lasting applications. It is produced by casting fluid plastic onto a movie, resulting in a thinner, a lot more conformable item that adheres well to contours and shapes.

On the other hand, calendared plastic is produced by a process that involves rolling and stretching vinyl sheets. This type is normally thicker and less costly than cast vinyl, making it suitable for temporary applications and level surface areas. While calendared vinyl supplies an affordable service, it might not perform also on elaborate styles or in extreme weather.

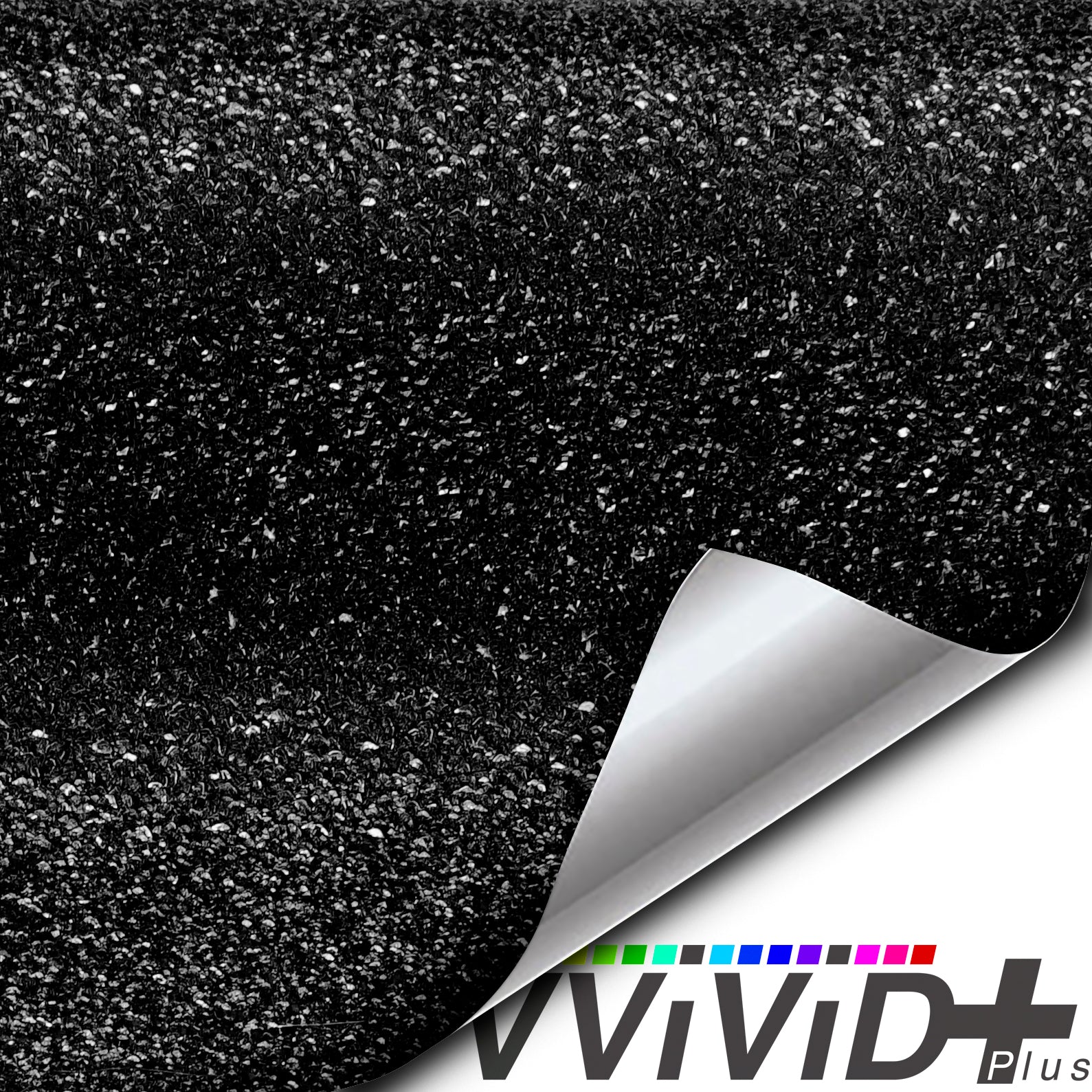

Additionally, specialized vinyl wraps are available, consisting of metallic, matte, and distinctive surfaces, which can boost appearances while supplying distinctive qualities. Recognizing these types of vinyl covers will enable you to make enlightened decisions based upon your task requirements, making certain optimal cause both look and durability.

Choosing the Right Complete

Picking the suitable surface for your vinyl wrap is an essential factor that can considerably affect the general aesthetic and functionality of your job. Plastic wraps come in a range of surfaces, each offering unique visual impacts and performance attributes. The most common surfaces include gloss, matte, satin, and distinctive choices.

A gloss surface offers a high-shine surface area that improves color vibrancy and depth, making it optimal for captivating styles. In comparison, a matte finish provides a subdued and innovative appearance, decreasing glow and flaws.

Satin finishes strike an equilibrium in between gloss and matte, supplying a soft shine that adds sophistication without overwhelming the style. Textured surfaces, such as combed steel or carbon fiber, can include a distinct responsive component, enhancing the aesthetic appeal of your task.

Ultimately, your selection of finish need to straighten with the desired visual and the environment where the cover will be applied. Consider resilience, maintenance, and the certain application to ensure ideal outcomes.

Installment Methods

Just how can you ensure a perfect application of plastic covers? The key lies in careful prep work and technique. Begin by cleaning up the surface area thoroughly to eliminate grease, dirt, and wax, as any type of deposit can compromise attachment. A clean, smooth surface area is vital for optimum outcomes.

Next, gather necessary devices such as a warmth gun, squeegee, and utility knife. These tools will help in using the plastic efficiently and cutting excess material. When applying the wrap, job in areas, beginning with one edge and delicately unfolding the plastic while using the squeegee to remove air bubbles.

Warm can be beneficial in this process; it makes the plastic extra flexible, enabling it to conform to contours and shapes easily. Workout persistence and avoid rushing, as this can lead to misalignment or bubbles. In instances of challenging locations, such as around edges or takes care of, consider making use of a method called "tack and stretch" to develop a smooth fit.

Upkeep Tips

To keep the stability and look of plastic wraps, regular care is essential. Prevent harsh chemicals, as they can damage the vinyl.

Dry the surface extensively after washing, as water places can become permanent if entrusted to dry naturally. For included security, think about applying a specialized vinyl cover sealant, which can aid keep the color and avoid fading from UV exposure.

Furthermore, prevent car parking in direct sunshine for extensive durations, as prolonged direct exposure can bring about staining and degradation of the cover. When possible, utilize a car cover or park in shaded areas.

Regularly inspect the wrap for any signs of lifting or damage. Resolve them immediately to protect against more degeneration if you see any type of problems. Following find here these upkeep pointers will certainly guarantee that your plastic cover remains dynamic and expands its lifespan, eventually enhancing the appearances of your job.

Typical Errors to Stay Clear Of

When it pertains to vinyl covers, staying clear of common mistakes can significantly influence both the application procedure and the durability of the wrap. One constant error is overlooking surface prep work. Appropriate cleansing and priming are vital to make sure that the plastic adheres effectively. Any type of dirt, grease, or old adhesive can lead to premature lifting or bubbling.

One more usual mistake is selecting the wrong kind of vinyl for the specific application. Different jobs need various materials; for example, a car cover should use cast vinyl for toughness, while a short-term sign might be sufficiently offered by calendared plastic.

Inadequate warmth application during installation can also cause issues such as creases and inappropriate adherence. Making use of a heat weapon at the right temperature is crucial for collaborating with the vinyl, specifically in difficult locations like edges or curves.

Lastly, forgeting post-installation treatment can reduce the life-span of the wrap. Failing to comply with upkeep standards, such as preventing harsh chemicals or unpleasant cleansing tools, can lead to damage. By steering clear of these mistakes, you can improve the performance and visual allure of your vinyl cover project.

Final Thought

In final thought, selecting the proper vinyl wrap demands cautious factor to consider of numerous elements, consisting of the type of vinyl, finish alternatives, and installation methods. Appropriate preparation and adherence to best methods are crucial for accomplishing optimum results and making certain the long life of the wrap. By preventing usual pitfalls and making informed decisions, individuals can effectively boost the aesthetic allure and resilience of their tasks via the strategic usage of vinyl wraps.

Plastic covers can be generally categorized into two major types: cast vinyl and calendared vinyl.On the various other hand, calendared Learn More Here vinyl is produced by a procedure that entails rolling and extending vinyl sheets.Choosing the appropriate surface for your vinyl wrap is an essential aspect that can dramatically affect the total visual and capability of your job.When it comes to vinyl wraps, avoiding usual challenges can significantly influence both the application process and the durability of the wrap.In conclusion, selecting the suitable vinyl cover demands careful look at this site factor to consider of various aspects, consisting of the kind of vinyl, surface options, and installation strategies.

Report this page